Partial Inventory of HFT SolidWorks Models

2/15/2012

Accessing models

All the models and children are in a single zip file:

http://www-rnc.lbl.gov/~wieman/container_jan_2011.zip

After unzipping, the models can be accessed with SolidWorks 2010 or e-drawing 2010

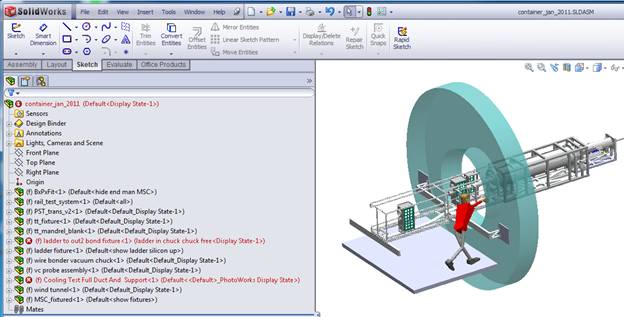

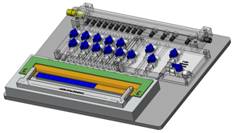

What you will see when you open the top assembly: container_jan_2011.SLDASM

Lower level models can be opened directly in the container_jan_2011 folder (unzipped) or they can be selected from within the top level assembly which is shown above.

WBS – Model Table

|

WBS |

WBS task |

Relevant Models and related documents |

|

1.2.1 |

Pixel Mechanics |

|

|

1.2.1.1 |

Module Support (sector) |

PXL.SLDASM wind tunnel.SLDASM |

|

1.2.1.2 |

D-Tube and Kinematic Mounts |

PXL.SLDASM tt_fixture.SLDASM tt_mandrel_blank.SLDASM |

|

1.2.1.3 |

Insertion Mechanism and Internal Service Supports |

PXL.SLDASM BxPxFit.SLDASM rail_test_system.SLDASM rc_fixture_asm.SLDASM RailandKinematicMountOverview.ppt |

|

1.2.1.4 |

PXL Engineering effort (post CD-1) |

Cooling Test Full Duct And Support.SLDASM rail_test_system.SLDASM wind tunnel.SLDASM |

|

1.2.2 |

Detector Assembly |

|

|

1.2.2.3 |

Phase-2 Sensor |

vc_probe_assembly.SLDASM |

|

1.2.2.4 |

PXL Sensor Production |

vc_probe_assembly.SLDASM |

|

1.2.2.6 |

Proto Det Ladder Assembly |

wire bonder vacuum chuck.SLDASM |

|

1.2.2.8 |

PXL Ladder production |

wire bonder vacuum chuck.SLDASM ladder fixture.SLDASM |

|

1.2.3.1 |

Sector Assembly |

PXL.SLDASM ladder to out2 bond fixture.SLDASM |

|

1.2.3.3 |

Sector Mount and Survey |

grand_master_kin_assembly.SLDASM PXL.SLDASM |

|

1.2.3.4 |

Final Assembly |

BxPxFit.SLDASM PXL.SLDASM Box_Insertion_N.SLDASM BxS.SLDASM |

|

1.2.4 |

Infrastructure |

|

|

1.2.4.1 |

Installation |

BxPxFit.SLDASM |

|

1.2.4.6 |

Cooling Services |

Cooling Test Full Duct And Support.SLDASM |

|

1.5.1 |

Integration and Global supports/ Mechanics |

|

|

1.5.1.1 |

Inner Detector Support |

Pixel_Insertion_Tube_asm.SLDASM |

|

1.5.1.2 |

Middle Support Cylinder |

MSC.SLDASM MSC_fixtured.SLDASM PST_trans_v2.SLDASM Pixel_Insertion_Tube_asm.SLDASM |

Table linking WBS numbers with relevant models and instruction documents

Model Descriptions

align_LACE.SLDASM and align_LACW.SLDASM

Alignment tool for locating the PXL box rails coaxial with the MSC rails in preparation for trasfere of the PXL detector from the box to the MSC in STAR. This is a subassembly of Box_Insertion_N.SLDASM.

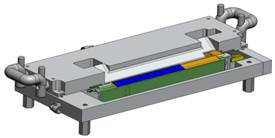

Cooling Test Full Duct And Support.SLDASM

The assembly used in the full size cooling test of the PXL detector. This assembly has developed a rebuild error that can be fixed at a future date.

Box_Insertion_N.SLDASM (a subassembly of BxPxFit.SLDASM)

The PXL storage box is equipped with rails and guides and alignment tools to facilitate the insertion of the PXL detector into STAR.

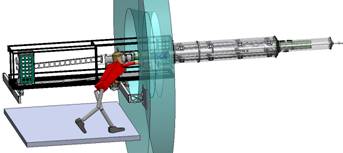

BxPxFit.SLDASM

PXL detector with MSC, PXL storage and insertion box, and magnet end cap.

BxS.SLDASM (a subassembly of BxPxFit.SLDASM)

Support for PXL insertion box with position adjustment

grand_master_kin_assembly.SLDASM

This is a multi-function fixture. It is used to position the PXL detector in the CMM for spatial calibration, to hold kinematic mounts in the PXL insertion tests and to locate the kinematic mounts in the PST for bonding.

ladder fixture.SLDASM

Assembly fixture used to fabricate ladders. Used for positioning and bonding silicon chips and other ladder bonding steps. Uses vacuum chuck hold downs.

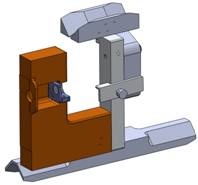

ladder to out2 bond fixture.SLDASM

This vacuum chuck tooling is used for bonding ladders to sectors. There are 2 other variations of this fixture which are not included in this collection. This assembly has developed a rebuild error that can be fixed at a future date, none the less it probably correctly represents the as built device.

MSC.SLDASM

Middle Support Cylinder – support structure for the PXL detector. The MSC includes insertion rails, cam tracks and kinematic mounts for the PXL detector.

MSC_fixtured.SLDASM

This assembly is the full MSC with fixturing to do various bonding and cutting operations in the fabrication of the MSC. This is a superposition of two assemblies with their tooling, the PIT ( Pixel_Insertion_Tube_asm.SLDASM ) and the PST ( PST_trans_v2.SLDASM ). These two assemblies are shown separately below.

Pixel_Insertion_Tube_asm.SLDASM (a sub assembly of MSC_fixtured.SLDASM )

This assembly is the PIT with fixtues. There is a superposition of several fixtures that are used at different steps of bonding and cutting. The two end pieces are designed for an additional use, the bonding of flanges and SSD supports on the OSC.

PST_trans_v2.SLDASM (a subassembly of MSC_fixtured.SLDASM )

PST tube with fixturing for bonding required components such as end flanges and the kinematic mounts used to support the PXL detector.

PXL.SLDASM (a subassembly of BxPxFit.SLDASM)

PXL detector with support carriage and bulkhead.

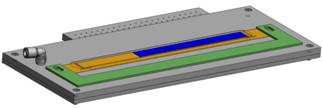

rail_test_system.SLDASM (partial view)

This view shows the working parts of the rail test system. This is the rail test system that will be used to test the PXL insertion mechanism. The test system is composed of rails and cam tracks with supports. This is to prototype the functionality of the PIT with its rails and cam tracks. The complete assembly is shown below.

rail_test_system.SLDASM

This complete assembly is a collection of overlapping structures. The assembly includes fixturing parts for positioning and bonding parts into the rail system.

tt_fixture.SLDASM

D tube with fixturing for bonding aluminum termination parts to the carbon structure.

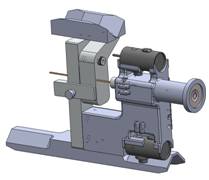

rc_fixture_asm.SLDASM

Fixture for drilling and gluing 20 mm composite rails that go in the MSC

tt_mandrel_blank.SLDASM

Mandrel for forming the carbon fiber D tube plus a trimming tool for cutting the ends of the D tube.

vc probe assembly.SLDASM

Vacuum chuck for holding thinned silicon chips in the probe station.

wind tunnel.SLDASM

Wind tunnel for checking vibration of a single PXL sector

wire bonder vacuum chuck.SLDASM

Vacuum chuck for wire bonding thinned PXL chips to the flex PC cable.