Stress as a Function of Ellipse Aspect

Author: H. Wieman

Company: LBNL

Date: 17-Jan-2005

1. Introduction

2. Description

3. File Information

4. Materials

5. Load & Restraint Information

6. Study Property

7. Stress Results

8. Design Scenario Results

9. Conclusion

10. Appendix

1. Introduction

Vacuum load stress increases with deviation from round.

This study quantifies the increase in stress as the

starting shape is varied from round to elliptical

2. Description

This study is for a beryllium tube

400 mm long

0.5 mm wall thickness

4 mm by 4 mm end ring reinforcment

The stress is determined for 4 different starting shapes

ranging from round (minor axis = 29 mm) to an ellipse

with a minor axis of 11.6 mm. The major axis is fixed

at 29 mm.

3. File Information

|

Model name: |

EllipticalTube3 |

|

Model location: |

C:\Documents and Settings\Howard Wieman\My Documents\aps project\mechanical\beam pipe\Beryllium Eliptical Stress Study\EllipticalTube3.SLDPRT |

|

Results location: |

C:\temp |

|

Study name: |

EllipseStress |

4. Materials

|

No. |

Shell Name |

Material |

Thickness |

|

1 |

Shell-1 |

4 mm |

|

|

2 |

Shell-2 |

0.5 mm |

5.

Load & Restraint Information

|

Restraint |

|

|

Restraint-1 <> |

on 1 Edge(s) fixed. |

|

Description: |

|

|

Load |

|

|

Pressure-1 <> |

on 3 Face(s) with Pressure 15 psi along direction normal to selected face |

|

Description: |

|

6. Study Property

|

Mesh Information |

|

|

Mesh Type: |

Shell mesh using surfaces |

|

Mesher Used: |

Standard |

|

Automatic Transition: |

Off |

|

Smooth Surface: |

On |

|

Jacobian Check: |

4 Points |

|

Element Size: |

4.9028 mm |

|

Tolerance: |

0.24514 mm |

|

Quality: |

High |

|

Number of elements: |

2304 |

|

Number of nodes: |

4636 |

|

Solver Information |

|

|

Quality: |

High |

|

Solver Type: |

FFEPlus |

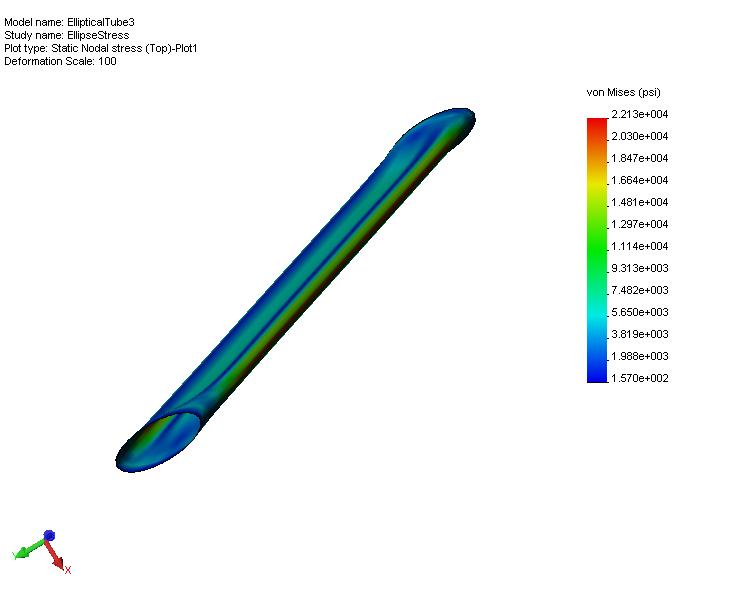

7. Stress Results

|

Name |

Type |

Min |

Location |

Max |

Location |

||||||||||

|

Plot1 |

VON: von Mises stress |

|

|

|

|

|

EllipticalTube3-EllipseStress-Stress-Plot1 |

|

JPEG |

|

|

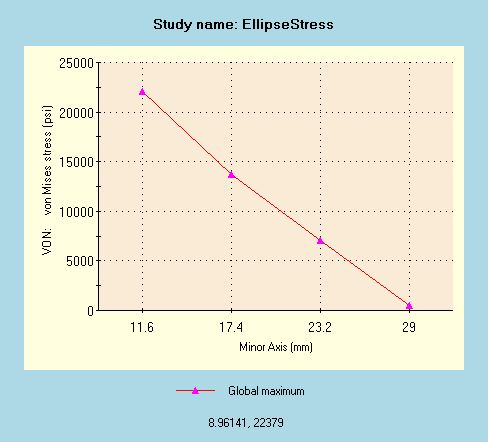

8. Design

Scenario Results

|

|

|

||||

|

Input Parameters |

Units |

Set1 |

Set2 |

Set3 |

Set4 |

|

MinorAxis |

mm |

29 |

23.2 |

17.4 |

11.6 |

|

|

|

||||

|

Results |

Units |

Set1 |

Set2 |

Set3 |

Set4 |

|

Result Status |

|

Summary |

Summary |

Summary |

Detailed |

|

Global maximum for the whole model |

|||||

|

VON: von Mises stress |

psi |

538.43 |

7075.5 |

13688 |

22127 |

|

P1: |

psi |

183.69 |

3575.6 |

5654.3 |

7390.6 |

|

P2: |

psi |

-76.249 |

-1849.9 |

-3684.5 |

-5939.2 |

|

P3: |

psi |

-491.87 |

-7687.2 |

-14812 |

-23675 |

|

URES: Resultant displacement |

in |

4.1012E-005 |

0.00098044 |

0.00163 |

0.0020465 |

|

INT: Stress intensity |

psi |

598.88 |

7798.8 |

15186 |

24683 |

|

ESTRN : Equivalent strain |

|

8.5328E-006 |

9.4309E-005 |

0.00016957 |

0.0002561 |

|

EllipticalTube3-EllipseStress-Design Scenario Results-Graph1 |

|

JPEG |

|

|

9. Conclusion

Stress = 538 psi + (29 mm - minor axis)*1127psi/mm

yield stress = 34800 psi

So a 1 mm difference between minor and major axis

gives a 21 safety factor

10. Appendix

|

Material name: |

|

|

Description: |

|

|

Material Source: |

Library files |

|

Material Library Name: |

hwmaterials |

|

Material Model Type: |

Linear Elastic Isotropic |

|

Unit system: |

English (IPS) |

|

Property Name |

Value |

|

Elastic modulus |

4.3954e+007 psi |

|

Poisson's ratio |

0.27 |

|

Shear modulus |

1.9583e+007 psi |

|

Mass density |

0.066836 lb/in^3 |

|

Tensile strength |

53673 psi |

|

Yield strength |

34815 psi |

|

Thermal expansion coefficient |

6.1111e-006 /Fahrenheit |

|

Thermal conductivity |

0.0026758 BTU/(in.s.F) |

|

Specific heat |

0.43598 Btu/(lb.F) |